Keep it simple – the new Pendix eDrive IN

863 days ago

5 minutes

At the last IAA mobility, LEVA-EU member Pendix, market leader for retrofit drives in the bicycle market, presented a revolutionary drive that is to be used mainly in the B2B sector for cargo bikes. This gives Pendix an additional pillar for the retrofit drive, because the Pendix eDrive IN creates new possibilities for bicycle construction, but is installed directly by the OEMs. There are already numerous interested parties and pre-orders, although the drive has not yet been delivered. Christian Hennig was in charge of the development. We spoke to him about the drive.

The Pendix eDrive IN is available as an innovative serial hybrid variant and in combination with a chain drive, i.e. a mechanical drive train. How did the idea come about?

The market for cargo bikes is growing and growing, the bikes are also becoming more and more popular in the professional sector. We have therefore thought about how we can meet the requirements for an electric drive specifically for this application. Both privately and commercially used bikes should focus on the necessary performance in order to be able to move heavy loads safely and comfortably. Of course, reliability also plays an important role, especially if a cargo bike is to be used as a replacement for a car.

The new drive system caused quite a stir at the IAA in Munich. Why?

The serial hybrid system in particular is better suited for cargo bikes by one decisive characteristic. By using a pedal generator, all mechanical wear parts of the conventional drive train such as chains, chainrings, or sprockets are eliminated. This increases reliability and significantly reduces maintenance costs. In addition, the entire space between the wheels can be used.

How does the Pendix serial hybrid version work?

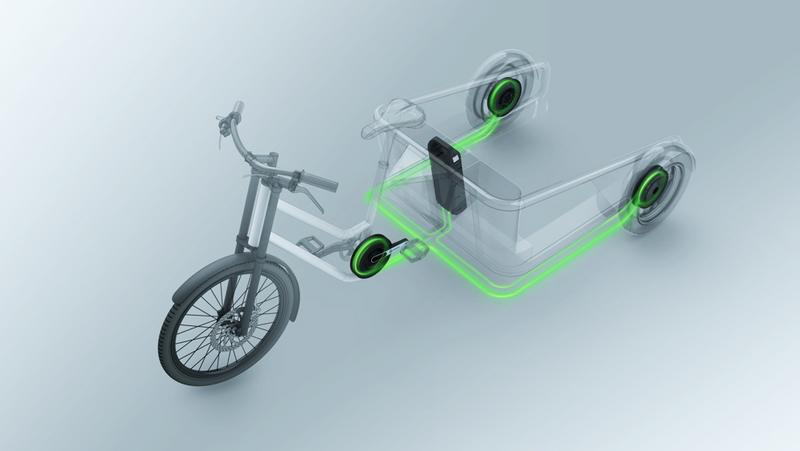

The system basically consists of a pedal generator, one or more drive motors, and a battery. The pedal generator is located on the bottom bracket, which converts the mechanical pedaling movement of the rider into electrical energy and then transmits this directly to the drive motors in the rear wheels. The generator can generate torque to give the rider a natural pedaling feel, very similar to that of a conventional bike. In addition to the driver’s performance, additional energy is supplied to the drive motors from a battery in order to ensure the necessary performance for moving a cargo bike safely and comfortably.

Where do you see potential uses for the new drive?

I see possible uses in cargo bikes where it is important to use the available space in the best possible way. In newer vehicle concepts, in particular, one often sees a very elaborately designed drive train with up to four chains connected in series in order to mechanically transmit the power from the driver to the rear wheels. This is exactly where there is a great advantage since the installation space can be used. In addition, many wearing parts of the mechanical power transmission are eliminated, which often cause unwanted downtimes of the bicycle, especially with intensively used cargo bikes.

There are already other manufacturers who also offer a serial hybrid drive. Are there any significant differences in the functions? What are the advantages of your product?

In principle, the functionality and range of functions of the various systems are quite similar. Our previous Pendix eDrive system was always developed according to the principle of “keep it simple”, and we are continuing this with this product. Generator and drive motors are based on the same engine concept and have been optimized in terms of function. Here, too, we offer a system in which the components come from a single source and are perfectly matched to each other. Functions such as gear shifting or reversing can be solved by software in the future. Of course, our proven Pendix.bike PRO app will also be used with this product in order to be able to provide the rider with useful information, customization of the riding profile and firmware updates over-the-air, and at the same time to support the service partner with diagnosis.

At the end of the day, is the vehicle actually still a pedelec?

This question can be answered with a clear yes. After years of back and forth, the European Commission decided at the beginning of 2022 that bicycles with a serial-hybrid drive system are on an equal footing with conventional pedelecs with a mechanical drive train. In order to maintain technology neutrality, it doesn’t matter whether the bike is equipped with a mechanical chain or not – as long as the drive only provides support and the rider also pedals. For us, our new drive was the next step in bicycle evolution right from the development stage. That’s why we’re happy to now also have support from Brussels.

LEVA EU

Campaign success

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Member profile

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.